Casting Facilities

Casting Capability

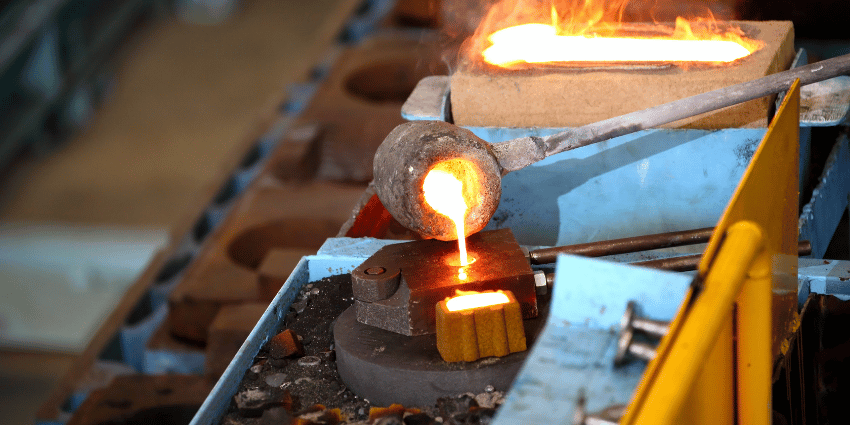

TECHNOSOL PROCESSES Operates from a exclusive integrated Casting Facilities located in Machenahalli Industrial Area, Shimoga. Purpose-built for high-quality ferrous casting production, our infrastructure is optimized for efficiency, precision, and consistent output.

Foundry Capabilities:

Sand Moulding Units – CO₂ and No-Bake setups

Shell Moulding Section – for high-accuracy small-medium parts

Induction Melting Furnaces – capable of handling various ferrous alloys

In-house Pattern Development Support

Machining & Finishing Services:

CNC Turning Machines

Vertical & Horizontal Milling

Grinding, Drilling, and Tapping Workstations

Engraving, Nurling, and Surface Finishing Stations

Quality Assurance Lab:

Spectrometer for chemical composition validation

Hardness testers and surface finish measurement tools

Magnetic Particle and Ultrasonic Testing (NDT)

Digital micrometers, height gauges, and calipers

Casting Versality

Finished components are securely stored in our dedicated warehousing section before final dispatch. In addition to our own Casting Facilities, we are allied with a reliable group of foundry vendors in Shimoga to scale operations or versatility in varieties when needed, without compromising quality or delivery timelines.

Our infrastructure reflects our philosophy—efficient production, reliable process control, and uncompromising quality.